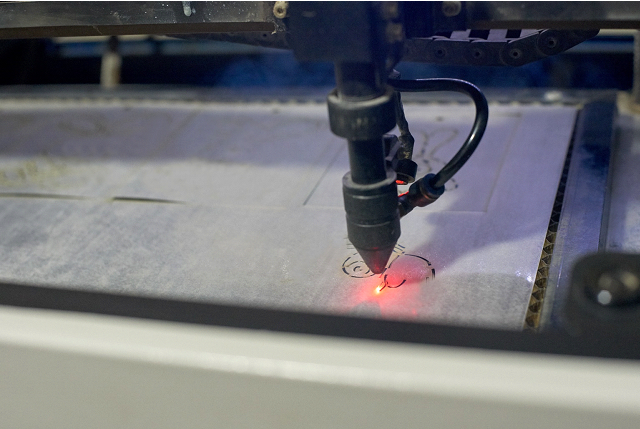

Lasers are commonly used for marking and engraving of materials. There are a wide range of applications found in the automotive, electronics/semiconductor, aerospace, medical, consumer products, gift & trophy, and food/beverage industries. It is a very flexible, basically maintenance- free process, and the results are very precise, creating sustainable marks on a large variety of materials. It is also low in consumable cost. When marking plastics, the exact color of the mark is highly dependent on the additives found in the plastic. A Mid IR Fiber-Laser, like our laser, emitting a 2.83 μm wavelength can, in most cases, engrave without color changes based on the melting of the material. Typically, this Mid IR Fiber- laser with 2.83 μm will be used for marking organic materials like wood, paper, cork, leather and horn and creates a dark contrast. Mid IR Fiber-Laser is more advanced solution that offers more flexible system that is easier to integrate into the manufacturing process compared with CO2 lasers that are in the past. The Mid IR Fiber-laser also removes paint or discolors fabric effectively. Glass marking is supported by our Fiber-lasers as well.

Fiber-Laser Marking and Engraving:

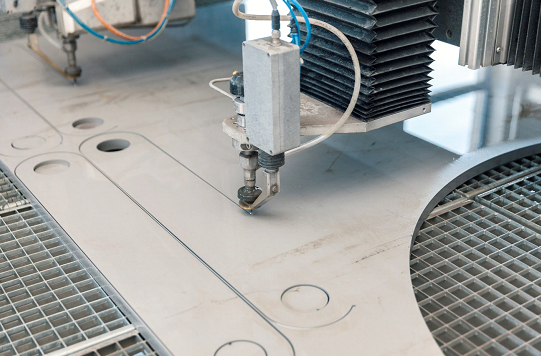

Fiber-Laser in Material Cutting:

Laser cutting is a mature industrial process with high flexibility, non-contact and stress free processes that produce finished parts direct from the tool. Laser cutting is a very precise process, with excellent dimensional stability, very small heat affected zone, and narrow cut kerfs. Various technologies are used in this process depending on the type of material to be cut. Plastics, ceramics, fiber-reinforced materials, and organics such as leather, fabric, paper, wood and others are processed ideally with CO2 lasers, and at the same time, Mid IR Fiber lasers like our new Fiber-Laser offers a better alternative that is more flexible and can cut wider variety of material faster due to its shorter Mid IR wavelength of 2.83 μm which offers optimal absorption to cut by evaporation or melting non-metal materials. Other brittle and transparent materials open the opportunity for use of our new Mid IR Fiber-Laser technology, for example, cutting of glass.